Hydraulic motors:

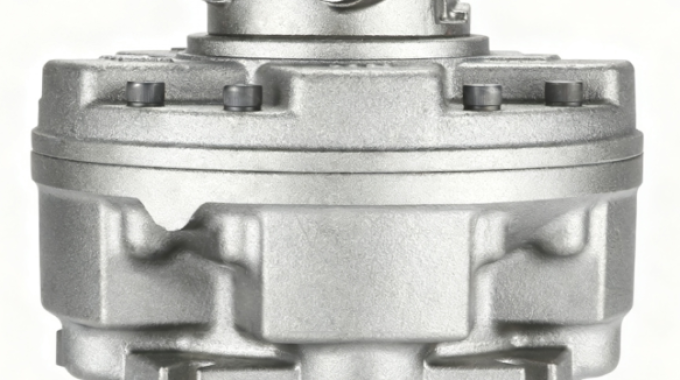

INM series hydraulic motor

IPM series hydraulic motor

IMB series radial plunger motor

IMC series two-speed radial plunger motor

I. Four Core Advantages for Extreme Marine Environments

Corrosion Resistance: stainless steel shell + special ceramic coating, no rust after salt spray test, complying with NORSOK M-001 standard;

Wide-Range Adaptability: Stable operation at -40℃~85℃, IP68 protection to isolate seawater, and resistance to typhoon-level strong winds of 60m/s;

High Efficiency & Precision: Permanent magnet synchronization technology achieves over 96% energy efficiency, saving 20%~30% energy, with a speed control accuracy of ±1rpm;

Long-Term Reliability: 15-year design life, and maintenance-free structure to reduce operation and maintenance costs.

II. Scenario-Specific Adaptation to Empower Core Operating Equipment

(1) Marine Cranes: Stable Heavy Load Control for Multi-Posture Operations

The motors feature 1.5x instantaneous overload capacity, and the field-weakening speed regulation technology meets the switching demand of “high speed under light load and low speed under heavy load”:

Fixed Boom Crane: permanent magnet motor, stable operation at 0-1500rpm;

Knuckle Boom Crane: high-torque motor, optimizing the coordination of multi-joint linkage;

Lattice Boom Crane: dual-motor redundancy design to ensure heavy load safety, with 10ms emergency braking response.

(2) Marine Winches: Constant Force Traction to Resist Dynamic Loads

The torque closed-loop control achieves ±2% tension accuracy, and the low-speed and high-torque characteristics are suitable for deep-water operations:

Mooring/Pipe-Laying Winches: Constant tension output to avoid steel cable breakage, adapting to load fluctuations caused by ocean waves;

Deep-Water Anchoring Winches: Stable torque in the low-speed range of 5-100rpm, enabling precise control of anchor chain lowering.